Digitalization

Digitalization in production

and operations

Data is the lifeblood of the digital transformation. This is especially the case in operations, with its massive volumes and varieties of data ranging from machine sensors to enterprise resource planning systems (ERP).

Through IIoT, Industry 4.0 and the Smart Factory, data, connectivity and disruptive digital innovations are becoming even more important – for existing factories as well as for new plants.

#manufacturing

PA helps companies transition their manufacturing systems to the future

With PA Facts we connect your physical manufacturing with the cloud to continuously increase the effectiveness and efficiency of your production, thus enabling the digital transformation of your production to predictive operations, prescriptive operations or even autonomous operations.

Unleashing optimization potential with analytics. Identifying and solving process and asset impacts before they occur. Use of AI to detect anomalies and optimize your operations.

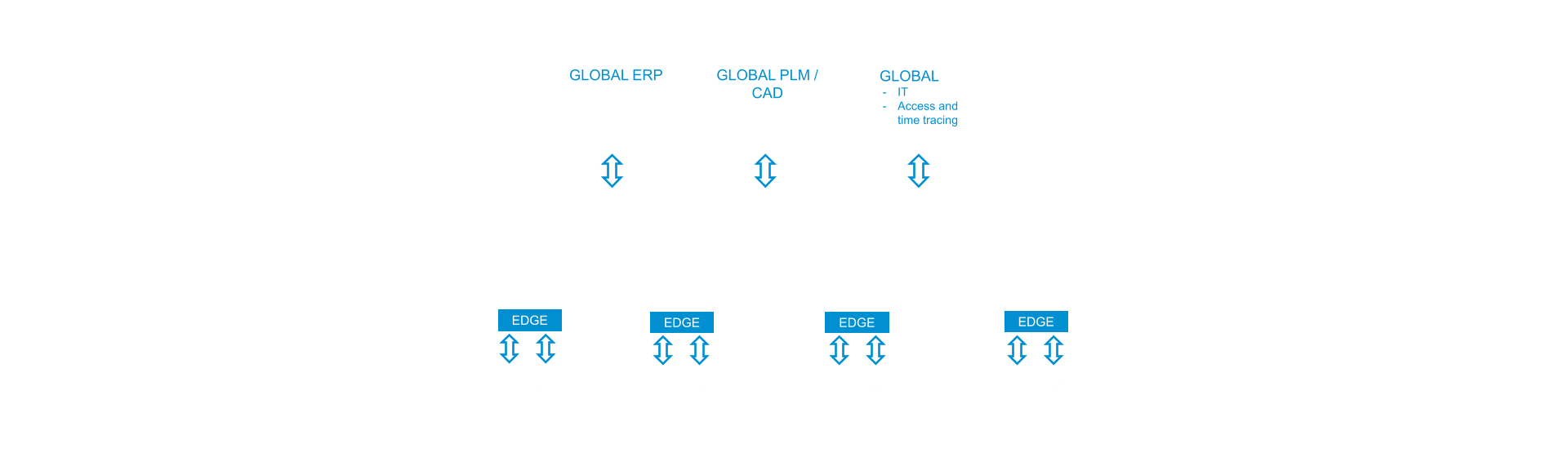

We offer the full range of OT system integration – from the factory floor, PLC, DCS, BMS and MES up to the ERP system.

Threats to OT and IT are different. For both sides, safety is of paramount importance. PA offers cyber security solutions for both OT and IT and for specialist fields as well.

Advanced Applications is part of the PA Group and is the SAP partner for the high-tech, medical technology, automotive, machinery, plastics, process production and retail sectors.

Why PA is the partner of choice for digitalization of production.

PA is system-agnostic. We work with leading systems and technologies, regardless of the supplier. The core of our business is integration and connectivity to deliver maximum benefit to our customers.

We support companies from strategy to implementation and scaling. Together with our industry knowledge and rich experience in digitalizing operations in the process and manufacturing industries, this makes us your partner of choice for the digitalization of production.

Digitalization that drives your operational performance.

Data enabling

Establishing a contextualized data lake by bridging the OT/IT gap

Reduction of downtime

Reduction of downtime in the high season through predictive maintenance

Major improvements in OEE

Major improvements in OEE using a production performance solution

Significant cost cuts

Significant cost cuts by establishing a single virtual center of operations for global production sites

Case Study AkzoNobel – Improving OEE with a digital solution

AkzoNobel improves its OEE with Performance Portal, a state-of-the-art IoT solution from Inimco, a PA company. An excellent example of digitalization in operations.

Learn about AkzoNobel’s approach and implementation success factors in our PA case study video.

How the digitization of production generates competitive advantages