Boosting Operator Effectiveness: Traditional vs. High-Performance HMI

In industries like chemical processing, operators manage complex processes under high-stakes conditions. The Human-Machine Interface (HMI) serves as the control hub, displaying data, notifications, and system statuses. However, Traditional HMI designs often overwhelm operators with excessive data, cluttered graphics, non-intuitive navigation and poorly designed notifications, increasing the risk of errors and delayed responses.

The Challenges:

Misconceptions About High-Performance HMI

Stakeholders in the process industry often misinterpret High-Performance HMI as simple, minimally colored displays. This narrow view overlooks its broader scope, which includes evaluating screen characteristics (e.g., size, resolution, luminance), sound design, related equipment (e.g., shutdown buttons, telephones), and control room ergonomics (e.g., screen mounting, multi-screen setups, videowalls).

Effective HMI design considers the operator’s cognitive abilities and work environment, not just visual triggers.

Shortcomings of Traditional HMI

Traditional HMI systems often rely on static, P&ID-like designs cluttered with data points and lack intuitive navigation or visual consistency. Operators struggle to monitor processes during routine operations due to the absence of clear overview displays. During process upsets, traditional HMIs can hinder rather than help by overwhelming operators with alarms of varying importance, leading to “alarm fatigue,” where critical alarms are overlooked.

These shortcomings can confuse and distract operators during critical situations, increasing the likelihood of errors. High-Performance HMI design, by contrast, transforms raw data into actionable information, enhancing user interaction through human-centric principles.

The solutions:

Human-Centered Design and ISA-101 Standards

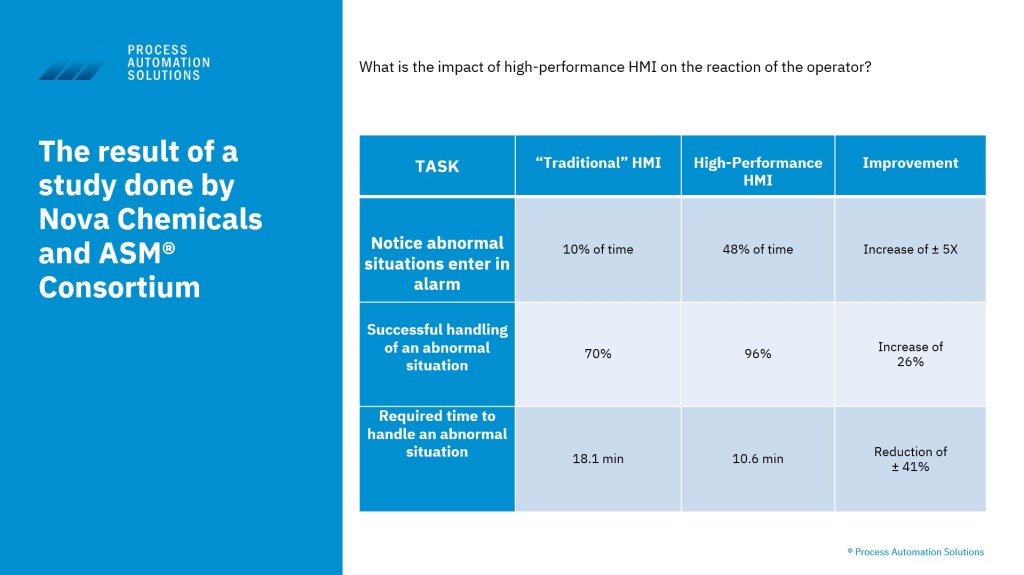

Recognizing the limitations of traditional HMIs, Nova Chemicals partnered with the Abnormal Situation Management (ASM®) Consortium to study human-centered design principles, guided by ISA-101 standards.

These principles prioritize simplicity, clarity, and effective information hierarchy. High-Performance HMI uses color-coding to differentiate statuses—reserving bright, saturated colors exclusively for critical alarms to avoid misinterpretation. By removing unnecessary details and grouping data hierarchically, it allows operators to focus on essential information.

The ISA-101 standard introduces a four-tiered display hierarchy:

- Level 1: Provides a “big picture” overview of the entire process.

- Level 2: Focuses on specific process units within an operator’s control.

- Level 3: Offers detailed displays for individual equipment or controllers.

- Level 4: Diagnostic screens for analysis, maintenance, or alarm management.

This structured approach reduces screen monitoring demands while improving situational awareness with a logical visual flow.

Enhanced Situational Awareness

High-Performance HMI enhances situational awareness—the ability to understand and anticipate issues—through advanced visualization techniques like trend indicators. Many industrial problems develop gradually, making trend data crucial for early detection. By embedding trend indicators, operators can quickly identify deviations and act before issues escalate.

The benefits of High-Performance HMI

The advantages of High-Performance HMI extend beyond aesthetics or navigation. They include improved safety, reduced human error, and faster, more informed decision-making. These systems minimize abnormal situations, equipment failures, and hazardous incidents, enhancing operational efficiency and reducing downtime.

This shift from traditional, data-heavy interfaces to intuitive, actionable displays represents a fundamental improvement in how operators interact with industrial processes. By equipping them with clearer, better-structured information, High-Performance HMIs empower operators to respond swiftly and effectively, driving safety and efficiency in high-stakes environments.

What Next?

The first step is to contact an expert to identify the specific needs and goals of your HMI challenges. Then, we will further develop the various layers to unlock the full potential of your HMI.